Rigid Supports Part II

Originally published at MITRA (Materials Information and Technical Resources for Artists) from the University of Delaware here:

(A most updated version found in this section:Resources)

Laminated Paper Boards and Museum Boards

Paper boards made from wood waste or wood pulp are sold under a variety of trade names including Upson Board and Beaver Board. Laminated paper boards should be thought of as temporary supports. They are highly acidic and have a weak physical structure, so they deteriorate quickly. Museum board is a high quality laminated paper board made of 100% cotton rag mat board. Museum boards have between two and eight distinct layers. As museum board lacks structural strength, for increased rigidity it should be mounted on a wooden auxiliary brace or panel.

Canvas Boards

Canvas boards are constructed from a thin layer of cotton or muslin primed with an acrylic dispersion ground that has been glued to a sheet of pulp cardboard. These boards should not be used if long-term preservation is a concern.

Aluminum

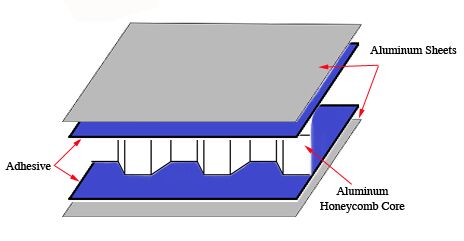

Aluminum panels, Aluminum Composite Material (ACM) panels, aluminum honeycomb panels, and Dibond panels have been widely used by artists since the late 1940s. Aluminum is more resistant to corrosion than other metals, can be cut easily with a band saw, and, depending on the size and thickness of the panel, will retain stiffness. It is necessary to note that, even in a stable environment, thinner pieces of aluminum will not remain planar.

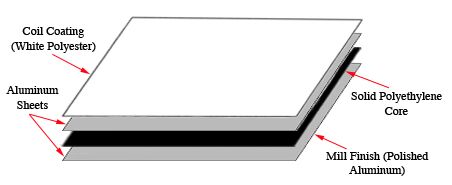

ACM boards differ by manufacturer but are typically composed of a thermoplastic core sandwiched between two lightweight sheets of aluminum. These boards can be purchased with two sides of exposed aluminum and no preparatory layer, with a canvas mounted to one side and a mill (polished aluminum) finish on the reverse, or with one side coated with a white polyester coil finish to protect the surface against corrosion.

Artefex ACM Panels are comprised of two sheets of 3mm aluminum bonded to a solid polyethylene core. They can be purchased with or without a preparatory layer and with or without one side covered with canvas. Dibond ACM Panels are made of two lightweight sheets of .010” aluminum with a thermoplastic core. They are available in a variety of colors.

The advantages of ACM panels over wood or stretched canvas are that they do not respond as readily to changes in RH and are not prone to insect damage.

Diagram showing the typical layering structure of an Aluminum Honeycomb Panel.

Diagram showing an example of the layering structure of an Aluminum Composite Panel (ACM).

Artists who choose to use these supports should:

Prepare the aluminum/ACM surfaces by removing the protective film. Degreasing the presentation side (typically the side coated with polyester) with ethanol or isopropanol. Create a tooth (e.g. 100/200 grit sandpaper) by lightly roughening the surface with an abrasive material NOTE: If a white protective polyester coil coating is present avoid breaking completely through it as this exposes the underlying aluminum and can lead to corrosion.

Avoid ACM panels that do not have a polyester coil coating (in industry ACM panels can be coated with a range of materials).

Choose a priming/ground material carefully. Priming/ground materials that are available in industry may be acceptable if they have been found to be compatible with certain ACM brands (Example: DTM Bonding Primer by Sherwin Williams has been found to be highly compatible with Dibond panels). As with most industry products, artists are encouraged to test these materials with their preferred painting technique.

Fix thinner supports to more rigid supports such as Masonite or construct a cradle (see instructions below). Sheets that are too thin are more prone to damage as they may flex and twist during transportation and handling.

Remember that “fat over lean” principles should be followed when applying alkyd, acrylics, and/or oil paints.

Understand that ACM panels with honeycomb or corrugated plastic cores (such as Artefex) tend to be lighter in weight than ACM panels that contain solid plastic cores.

Avoid subjecting the panel to extremely high temperatures (above 175 F).

Know that supports that are fairly heavy are at risk of planar deformation along the outer edges (e.g. bent corners) especially during transportation and handling.

Avoid painting directly on the surface of unprimed aluminum as this technique can lead to adhesion problems.

Consider applying an even coat of neutral pH PVA adhesive or certain acrylic polymers (e.g. high quality acrylic dispersion mediums or gels) when adhering canvas/paper to the surface of a panel following degreasing/cleaning of the surface. To adhere your canvas to a panel, the following steps are recommended:

Apply one even coat of PVA size or acrylic gel medium to the surface of the panel using a spatula or a brush. Lightly wet the reverse of the canvas (the side that will be adhered to the panel) with water to promote better adhesion. Use a brayer/bone folder to eliminate any air bubbles, working from the center outwards to the edges. If you have decided to keep excess fabric along the outer edges, fold them over and attach to the backside of the panel (or affix them later). Immediately apply another coat of PVA size or acrylic gel medium (stick to the same material you used previously) to the face of the canvas. Once the canvas has dried, apply a coat of PVA size or acrylic gel medium to the reverse of the panel to prevent potential warping.

Consider using BEVA 371 adhesive/film to adhere canvas to panel after the panel has been sealed. BEVA film (as opposed to the adhesive) will not penetrate the fabric support as readily as PVA adhesive or acrylic mediums might and the ability to re-activate the adhesive with heat makes it far easier to later address any unwanted air-bubbles should they form during the procedure. To adhere your canvas to a panel, the following steps are recommended:

Apply one to two even coats of dilute BEVA adhesive (thin cream consistency) to the panel after cleaning the surface and two coats to the reverse of the canvas (wear adequate protection as solvents are required). If you are using BEVA film it is better to use two sheets of film as opposed to one, although one sheet may be able to provide enough adhesion. Place the film with the BEVA-side facing the panel (or canvas if you are using two sheets) without removing the silicone-coated Mylar and apply heat evenly using an iron (BEVA adhesive requires a temperature of around 65.6 degrees Celsius to be re-activated). Weight down the surface until the BEVA has cooled and then carefully peel away the silicone-coated Mylar (NOTE: If you attempt to remove the Mylar too soon you will pull up the BEVA). If you are using two sheets, repeat this process with the other sheet of BEVA film when applying to the reverse of the canvas support (consider placing silicone-release paper/Mylar beneath the canvas when applying heat, silicone side facing up). Then position your canvas directly atop the BEVA film,

place silicone-release paper/Mylar (silicone side facing down) atop the canvas, and apply heat. If you are using BEVA adhesive simply wait for the coats of BEVA to dry (in a well ventilated space) and repeat the aforementioned step. If you experience difficulties using BEVA film, try applying a coat of adhesive to the back of the canvas or switch to the adhesive altogether.

Consider using a temperature controlled vacuum table if you wish to adhere a completed painting onto a panel (in general this is not recommended). It may be possible to safely adhere your composition if it does not contain thickly built up paint, wax-based additives, or areas of strong impasto. Follow the instructions above but consider using a soft blotter paper over your silicone release paper/ Mylar to protect more delicate surfaces (you may also need to raise the temperature of your iron ever so slightly).

Provide additional auxiliary support to large format panels and panels that are less than ¾” thick by attaching a brace or cradle by gluing strips of wood around the outside edge of the back of the panel using the following steps:

Obtain 1” by 2” wooden boards (oak or maple are preferred) and cut them down to match the outer dimensions of the support (overall size will depend on what type of join is used for the corners). ■■■■ and mitered tend to be the most common type of joins (consider using a 90 degree-corner clamp when making mitered corners), however lap joins are generally considered to be more structurally sound. Make sure that the wooden boards are perfectly aligned and flush with the outer edges by laying them on the reverse of the panel before gluing to the reverse (it can helpful to mark the position with a pencil). Use an appropriate adhesive (please refer to the Dibond Manual located in our reference section) to adhere the wooden boards in place while the glue is drying, clamp/weight the boards to avoid creating any air bubbles. For large-scale supports artists may choose to construct horizontal and/or vertical crossbars although crossbars should NOT be glued directly to the reverse of the panel, only fixed to the outer boards of the cradle using glue and/or hardware.

Copper

Artists have used copper supports since the 17th century for both practical and aesthetic reasons. Copper panels are durable and compact and are available in a range of portable sizes but are more prone to corrosion than aluminum. A copper support tends to give a warm tone to the overall composition as oil paints do not

sink into the ground as they do on canvas or wooden panels so they can remain intensely saturated even when applied in thin layers.

Artists who choose to use copper supports should:

Prepare the surface by degreasing the presentation side with solvents (e.g. mineral spirits followed by denatured alcohol) and creating a tooth by roughening the surface with an abrasive material. NOTE: There is no need to purchase costlier “polished” copper etching plates as artists are encouraged to abrade the surface anyhow to improve adhesion.

Sheets that are too thin are more prone to damage as they can flex and twist during transportation and handling. Select copper panels that are of an appropriate thickness (e.g. high quality copper etching plates).

Fix/adhere thinner supports to more rigid supports such as Masonite by globally applying an adhesive like epoxy in an even manner to the sheet and/or the rigid support (abrade the reverse of the panel prior to gluing to improve adhesion). In general, however, thin gauge copper panels should be avoided.

Remember that “fat over lean” principles should be followed when applying alkyd, acrylics, and/or oil paints.

Avoid aqueous-based ground/paint materials in order to prevent the formation of corrosion products.

Not paint directly on the surface of unprimed copper as this technique may lead to potential adhesion problems in the future.

Other Metal Supports

Tin, tin-plated iron, steel, zinc, and other metals have occasionally been used by artists as supports. Tin-containing supports are susceptible to corrosion when exposed to high humidity, oxygen, and atmospheric pollutants. Zinc supports are less prone to corrosion in humid environments than copper supports, but they are more susceptible to degradation when exposed to acidic or alkaline materials and conditions. A thin transparent film of zinc oxide (which appears as a bluish-white film) can form on a zinc panel when it is exposed to air. The zinc oxide then can react with fatty acids in oil and alkyd paints to form zinc soaps (which may protrude through the surface as unsightly pustules). Steel and stainless steel are not commonly used as supports due to the weight of these metal alloys. Steel is composed of iron and carbon with smaller additions of other metallic elements such as molybdenum, manganese, copper, chromium, or nickel. The larger percentage of chromium in stainless steel (a minimum of 10.5% by mass) is what gives it corrosion resistance.

Slate/Stone/Marble/Porphyry

It is likely that various stones have been used as painting substrates since antiquity. Stones or marbles that have a fine grain (are not porous) and can be evenly polished are the most suitable for use as painting supports. Stone supports are mechanically stable as they do not change with humidity fluctuations and are impervious to worms and insects. Brittleness, poor preparation of the surface, and poor application of the paint and ground layers (e.g. deviating from the fat over lean principle) can cause delamination.

Glass

Glass supports share the mechanical stability and insect resistance of stone supports, but possess a highly finished, non-porous surface. However, glass is inherently fragile and prone to breakage (particularly around the outer edges) and can become more brittle as its ages. As paint and ground layers can readily delaminate due to the slick surface, glass supports are not recommended. If artists choose to use glass supports, only frosted or sandblasted glass should be used and the surface should be degreased with ethanol or acetone before use.

Polyvinyl chloride (e.g. Sintra)

The main issue with the use of polyvinyl chloride-based plastics as painting supports is the presence of plasticizers and other additives which are added during the manufacturing process. Without testing, it is difficult to identify the specific polymer blends present within a polyvinyl chloride (PVC) sheet or to know how stable the material is. Over time, the plasticizers in a PVC sheet can migrate to the surface forming visible liquid drops which become tacky and then crystalline. The migration of plasticizers will likely cause delamination of the paint and/or ground layers. Sheets of PVC can warp and will sometimes grow mold when exposed to high levels of humidity and heat. Polyvinyl chloride is not recommended as a permanent support for works of art.

If the artist insists on using a PVC support, the best procedure is to paint on a properly primed canvas and adhere the finished canvas to the plastic sheet. This way, if the plastic support deteriorates, the canvas can be removed and adhered to new support.

Polycarbonate (e.g. Lexan)

Like polyvinyl chloride-based plastics, polycarbonates also tend to contain a wide range of additives that can pose potential problems for artists. Polycarbonates are long-chain linear polyesters of carbonic acid and dihydric phenols (e.g.

Bisphenol A). There are several grades of polycarbonate sheeting available today and distinguishing one from another really depends on the additives present which can include glass fibers, UV stabilizers, mold release agents, and flame retarders.

The presence/absence of these stabilizers will in turn affect the polycarbonate’s resistance to heat, its brittleness, and its tendency to degrade in UV light.

Polycarbonate can also be incredibly sensitive to certain solvents; artists should avoid bringing acetone, aromatics, and other solvents to surface of Plexiglass, sticking instead to water or mineral spirits-based products.

The primary concern regarding these additives is their tendency to migrate out of the substrate slowly over time (or quickly depending on the nature of the environment). For example, the migration of Bisphenol-A in clear polycarbonate plastics (e.g. water bottles) has been extensively studied, a phenomenon that could very likely cause delamination and/or flaking of the overlying ground/paint layers. It is for this reason that polycarbonate supports are not recommended for artworks that are intended to last.

Polymethyl Methacrylate (e.g. Plexiglas)

Plexiglass is one of several trademarked names used to market clear sheets of polymethyl methacrylate, a material that is a popular support among artists.

These sheets tend not to contain potentially problematic additives such as those found in polyvinyl chloride- and polycarbonate-based materials. However, Plexiglass will expand and contract in response to changes in temperature and humidity, leading to eventual warping or bending of the support. This can be problematic if very brittle materials are used in the paint and/or ground layers (e.g. oils, alkyds, certain resins) as delamination and cracking may occur as the support expands and contracts. Watercolors, tempera, and most gouache paints should be avoided. The glassy-like surface of Plexiglass makes for a surface that can be easily scratched and can build up a static charge that can attract dust particles. Plexiglass is prone to yellowing if exposed to UV light and can be extremely sensitive to certain solvents; artists should avoid bringing acetone, aromatics, and other solvents to surface of Plexiglas, sticking instead to water or mineral spirits-based products.

Finally, and perhaps most importantly, Plexiglass supports are inherently brittle and easily shatter or crack if dropped or damaged.

If an artist insists on using a polymethyl methacrylate support, the best procedure is to initially sand the surface in order to provide some mechanical tooth to improve the adhesion of the paint and ground layers. Artists should consider painting and priming with acrylics if using Plexiglass as they do retain some degree of flexibility. Avoid installing inflexible hardware directly into the Plexiglass, choose thicker rather than thinner sheets, and use a channeled frame to house/display the Plexiglass.

ADDITIONAL REFERENCES AND RESOURCES

General

“”Supports” in Th e Painter’s Handbook: Revised and Expanded by Mark David Gottsegen (New York: Watson-Guptill, 2006).

“History and Use of Panels or Other Rigid Supports” by Jorgen Wadum and Noelle Streeton in The Conservation of Easel Paintings , eds. Dr. Joyce Hill Stoner and Rebecca Rushfield (London and New York: Routledge, 2012).

Golden Artist Colors - Preparing a Painting Support Golden Artist Acrylics – Professional Acrylic Paints for Artists

CAMEO: Conservation and Art Materials Encyclopedia Online (Museum of Fine Arts Boston) http://cameo.mfa.org/wiki/Main_Page

Wood

Kress Technical Art History Website - Wooden Supports https://www.artcons.udel.edu/about-us/kress/historical-materials- techniques/wooden-supports

Golden Artists Colors - Understanding Wood Supports for Art - A Brief History by Elaine Salazar

http://oldsite.goldenpaints.com/justpaint/jp29article3.php

Britannica – Wood Science Wood | Properties, Production, Uses, & Facts | Britannica

Transport Information Services – Properties of Various Wood Species Wood species – Transport Informations Service

The Encyclopedia of Wood , U.S. Department of Agriculture, 2007 [portions available] The Encyclopedia of Wood - Agriculture - Google Books

%E2%80%A2+The+Encyclopedia+of+Wood,+USDA&source=bl&ots=MYUmCSV66b &sig=xUESVua9_cPCeLrPxf08t7N_2fQ&hl=en&sa=X&ved=0ahUKEwjard7PxZnOAhU CNSYKHbvzBaMQ6AEIcjAJ#v=onepage&q=%E2%80%A2%20The%20Encyclopedia

%20of%20Wood%2C%20USDA&f=false]

Hardboard, Fiberboard, etc.

Journal of the American Institute for Conservation (JAIC) -“Short communication early wood-fiber panels: Masonite, hardboard, and lower-density boards” by Alexander W. Katlan

Golden Artists Colors - Plywood as a Substrate for Painting http://oldsite.goldenpaints.com/justpaint/jp29article4.php

Ampersand - Painting Panels for Artists http://www.ampersandart.com/products_main.html

American Harboatd Association - Today’s Hardboard

Composite Panel Association http://www.compositepanel.org/

Composite Panel Association - MDF From Start to Finish

http://www.hardwoods-inc.com/sites/default/files/mdf_start_to_finish_2005.pdf

“Wood-based Composites and Panel Products” by John A. Youngquist in Forest Products Laboratory *Madison, WI: I.S. Department of Agriculture, 1999) http://www.carbeck.org/pdfs/FPL_Wood_Handbook_Ch10.pdf

Panel Processing, Inc. – “Hardboard (Masonite) What is it?” by RM Granum and O.B. Eustis https://harborsales.net/Portals/0/docs/hardboard_what_is_it.pdf

Aluminum

Dibond Fabrication Manual Graphic Display Products

%202011.pdf

Graphic Display, USA - Dibond Graphic Display Products

Natural Pigments - Artefex ACM panels http://www.naturalpigments.com/custom- artefex-panel.html

Jackson’s - Aluminum Painting Panels https://www.jacksonsart.com/blog/2014/03/28/aluminium-painting-panels/

SOS Graphics – Substrate List http://www.sosgraphics.ca/SOSMaterialList.pdf

Copper

Copper as Canvas: Two Centuries of Masterpiece Paintings on Copper, 1575–1775, ed. by Michael K. Komanecky (Oxford: Oxford University Press, 1998).

Plastics, etc.

Golden Artist Colors – Acrylics on Plastics Acrylics on Gold Leaf | Just Paint plastics

SOS Graphics Substrate List http://www.sosgraphics.ca/SOSMaterialList.pdf

Polycarbonates and other plastics http://www.ptsllc.com/intro/polycarb_intro.aspx

Plexiglas PLEXIGLAS® Acrylic Resins and Sheets | Trinseo et-docs/plexiglas-general-information-and-physical-properties.pdf

Plastics in Art: A Study from the Conservation Point of View , by Friederike Waentig (Petersberg: Imhof., 2008).

Plastics in Art: History, Technology, Preservation , by Thea van Oosten, Yvonne Shashoua, and Friederike Waentig (Munich: Siegl, 2002).